For different pressures or specifications, the valve seat has the following forms: 1. the valve seat ring is threaded or welded with the valve body,the threaded valve seat is easy to disassemble, maintain or replace,2. weld the sealing surface material on the valve body directly 3.For stainless steel valves, the sealing surface of the valve seat is directly machined on the valve body generally.

Middle flange gasket:

The valve body and bonnet are connected in the form of bolted flanges. The flange sealing gasket is as follows:

Below CLASS 600 and PN10.0Mpa Concave convex gasket seal

Above CLASS 600 and PN10.0Mpa Octagon ring gasket seal

The gasket is graphite filled metal spiral wound gasket with inner ring ( discarding the rubber asbestos plate used in the past), and the gasket is reliably sealed .With excellent recovery performance when disassembly and assembly.

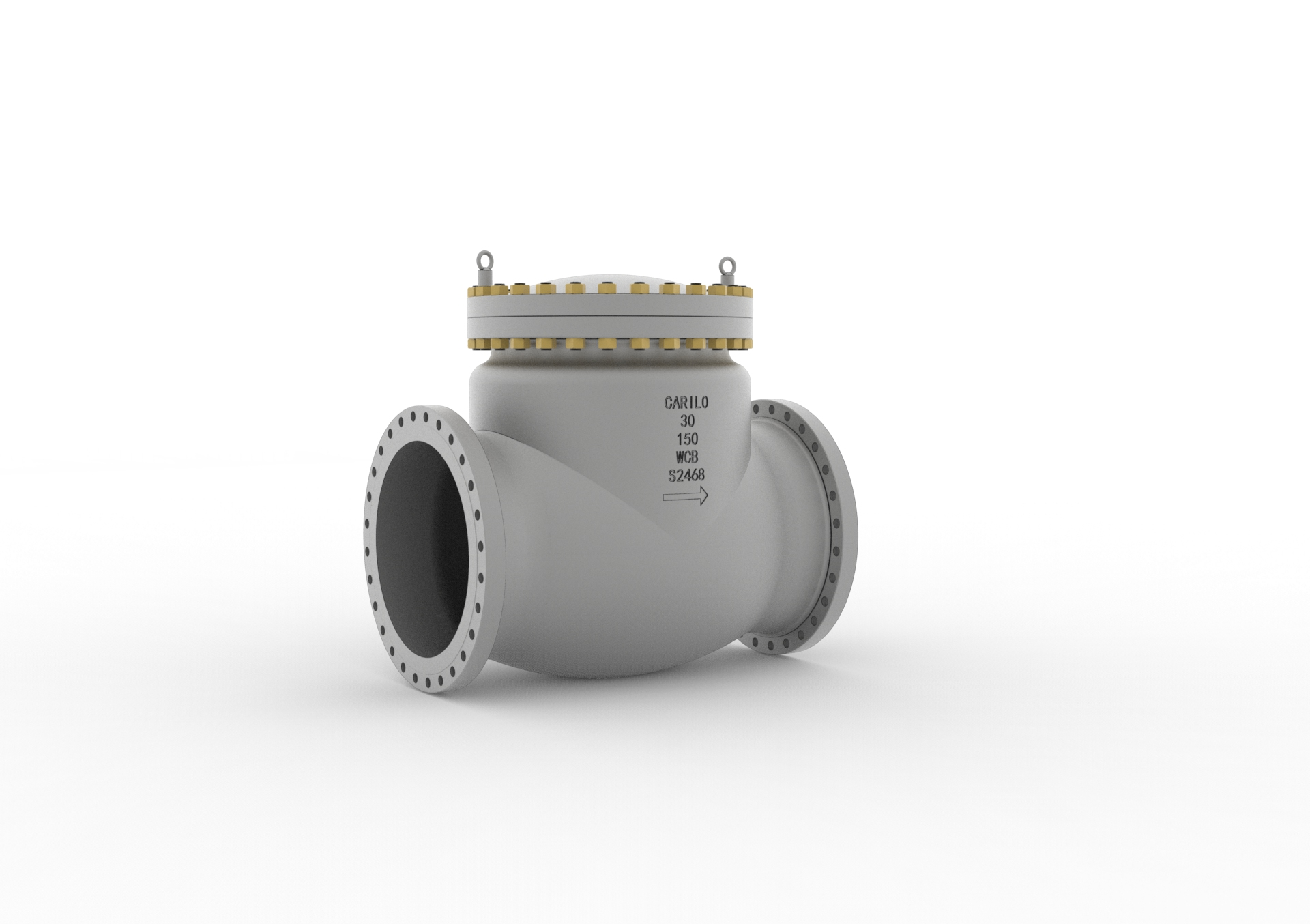

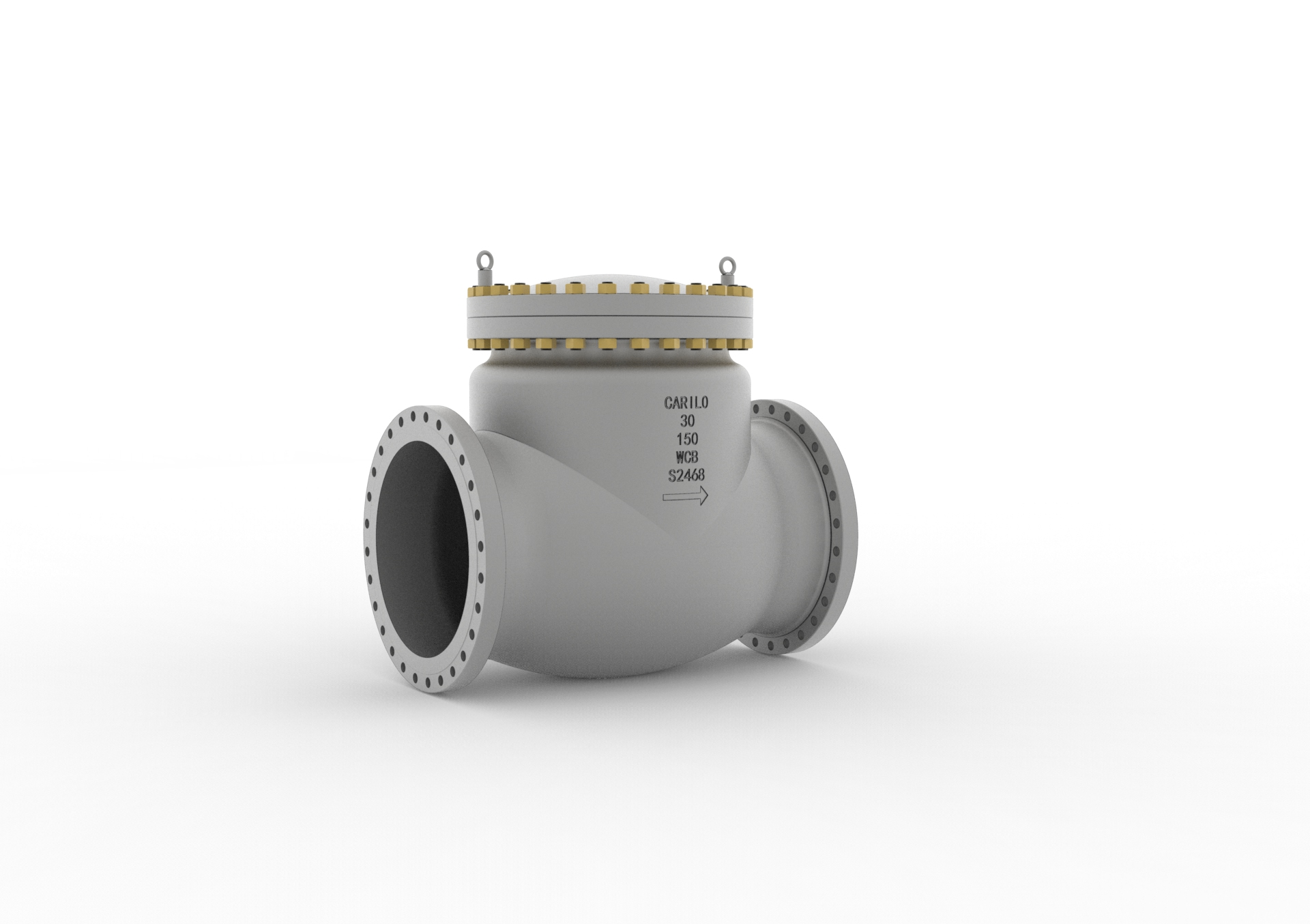

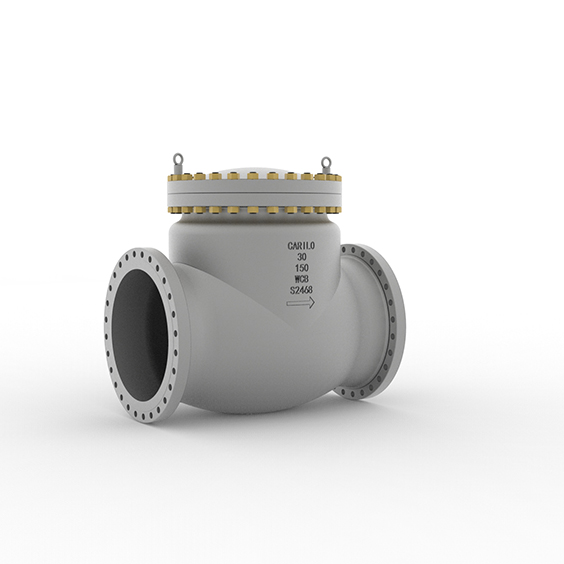

Product Range:

●Size: NPS 2’’ –36’’/DN50–DN900

●Rating: Class 150 – Class2500/PN10–PN420

●Material:WCB,WCC,WC6,WC9,CF8,CF8M,CF3,CF3M,CF8C,LCB,LCC

●Operation method: swing type,lifting type

Design descriptions:

●Bolted cover

●Horizontal or vertical service

●RF,RTJ,BW(Buttwelding)

●Swing type,Lift type

●Non-penetrate disc shaft

Applicable standards:

●Design& manufacture:BS 1868,ASME B16.34,API 6D

●Face to face:flanged,ASME B16.10,API 6D,EN 558.1,DIN 3202

●Flange ends: ASME B16.5,ASME B14.47,EN 1092-1

●Butt-weld ends: ASME B16.25,EN 12627

●Inspection and test:API 598,API 6D,EN 12266