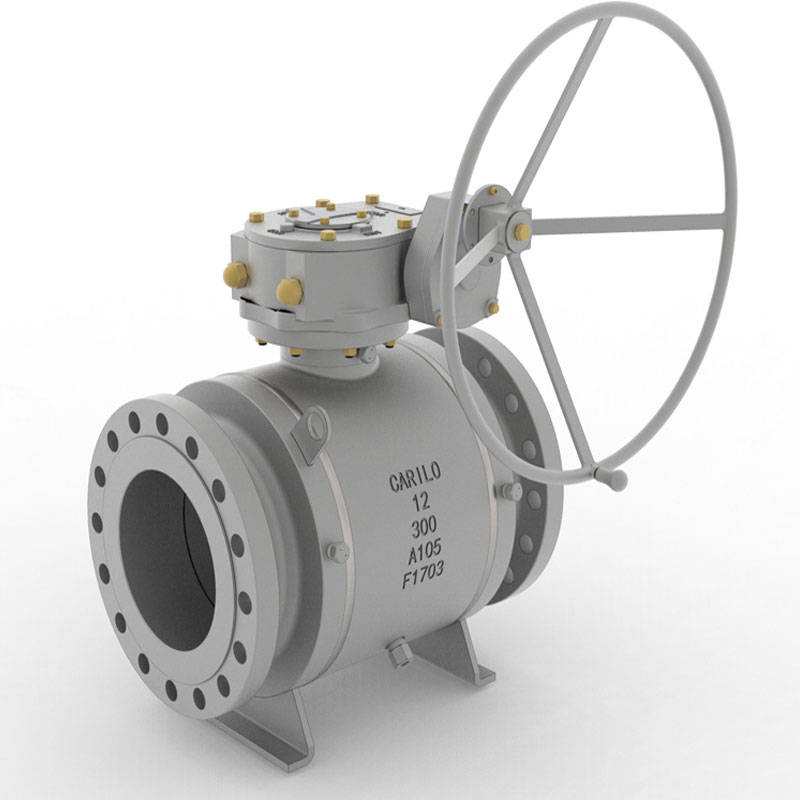

Fully welded rtunnion ball valve

Fully welded rtunnion ball valve

Due to the ball valve is fully welded structure, it reduces the risk of leakage. Integral body will ensure the tightness of body. The support plate structure also increases performance stability. Fully welded ball valves are used mainly in gas transmission and distribution pipeline, typical for underground and buried installation. Stem height can be adjusted according to pipe construction & design requirements.

Product Range:

●Size: NPS 2’’ – NPS 40’’/DN50 – DN1000

●Rating: Class 150 – Class 2500/PN16 – PN420

●Material: A105, LF2, A182 F304, F316, F304L, F316L, F51, F53, F55, F60, F321, Inconel, Incoloy, Hastelloy, Monel, Titanium, etc.

●Operation: Lever, gear, electric actuator, pneumatic Actuator

Design descriptions:

●Full port or reduced port

●RF, RTJ, BW

●Welded body

●Soft seat or metal to metal seat

●Anti statics device

●Blow-out proof stem

●Fire safe

●Double Block & Bleed (DBB), Double Isolation &Bleed (DIB)

●ISO 5211 Mounting pad

●NACE requirement

●Extended stem if required

●Fugitive emission if required

●Locking device (manual operation)

Applicable standards:

●Design& manufacture: API 6D/API 608/DIN 3357

●Face to face: API6D/ASME B16.10/DIN 3202/EN 558.1

●Flange ends: ASME B16.5/ASME B16.47/EN 1092-1

●Butt-weld ends: ASME B16.25/DIN 3239/EN 12627

●Inspection and test: API 598/API 6D/DIN 3230/EN 12266

●Fire safe: API 607/API 6FA

●Fugitive emission: ISO 15848-2/ISO 15848-1